Taller avanzado de Fusion en MakerFest 2026

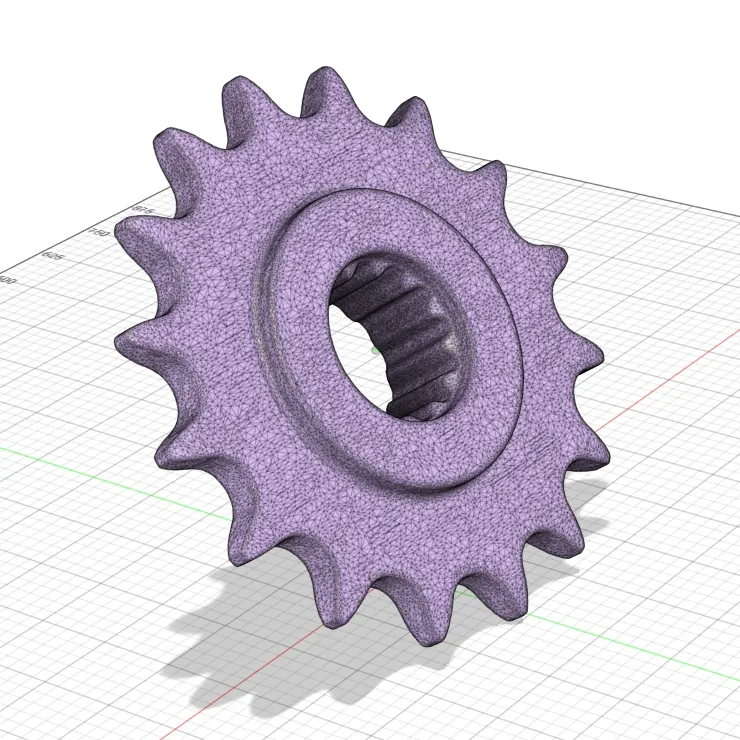

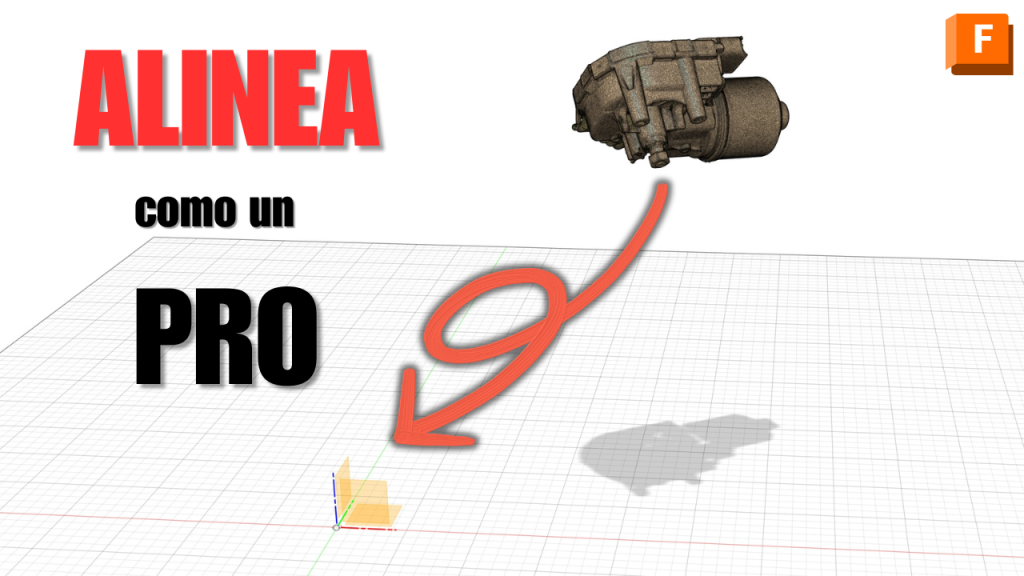

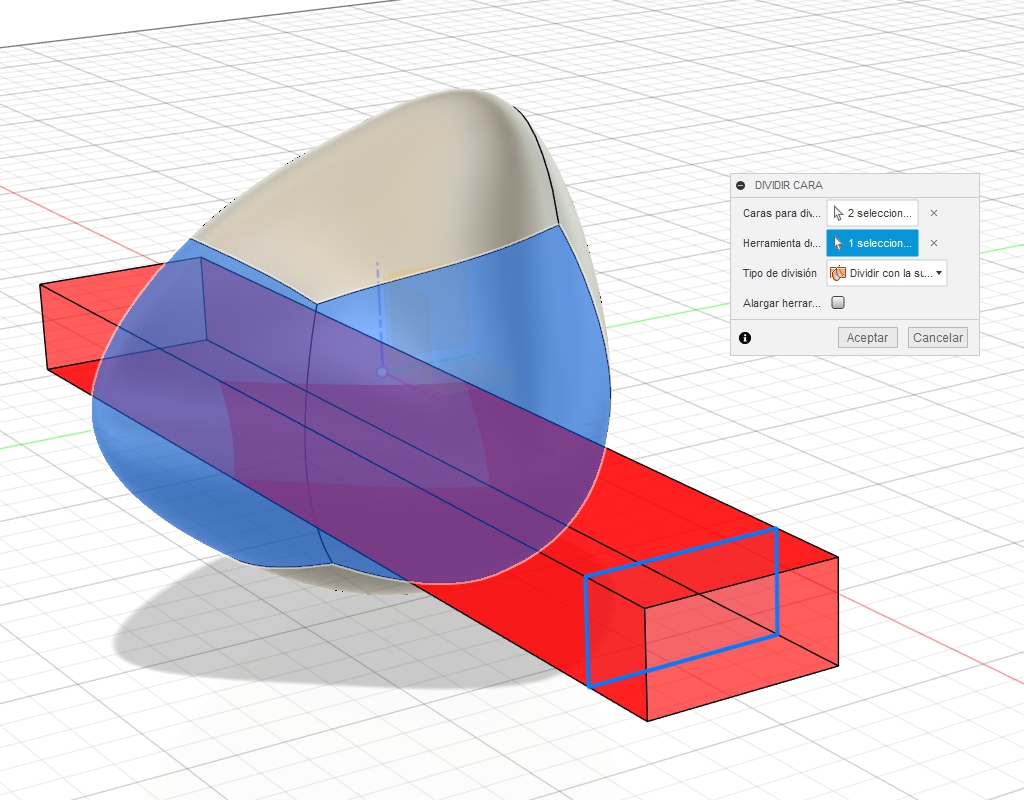

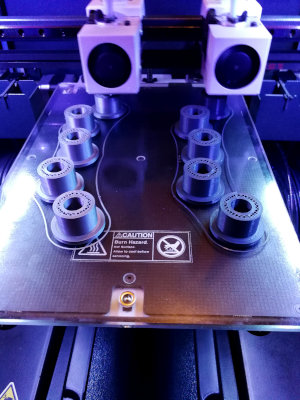

El sábado 31 de enero daré un taller avanzado de Fusion en Mollet del Vallès durante la MakerFest 2026. Esta es la pieza escaneada en STL que vamos a utilizar. link de descarga Se trata de insertar una malla escaneada en 3d y luego reproducir el diseño. Para ello se pueden utilizar varias técnicas. En […]

Taller avanzado de Fusion en MakerFest 2026 Leer más »